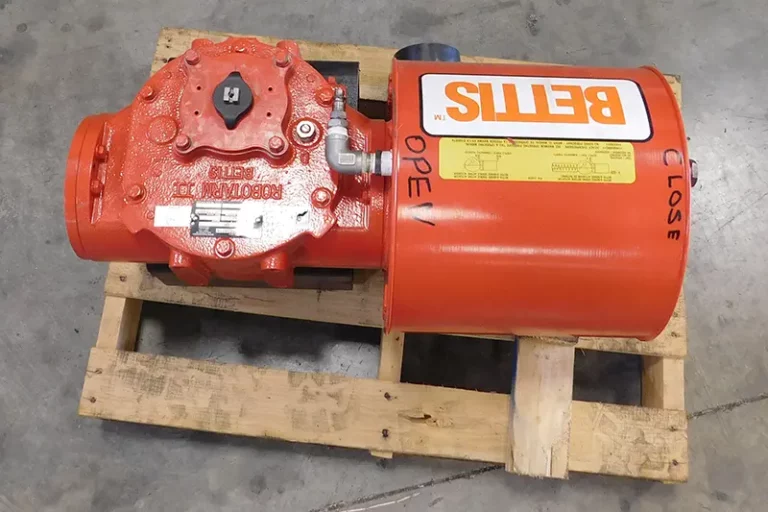

Pneumatic Valve Actuators for Process Control

Our experts offer supply and service options for pneumatic valve actuators for all applications and valve types. We specialize in industrial actuators to provide you with the detailed service you need to keep your actuators in peak operating condition.

Pneumatic actuators use pneumatic technology to control valve position. These actuators use compressed air that pushes against a diaphragm to control whether the valve is opened or closed. They come in both linear and rotary options for controlling industrial valves.

Pneumatic valve actuators may be single acting or double acting. Single acting industrial actuators use one port where the pressurized air enters. They use a spring to return to the default position. Double acting actuators use two ports for the pressurized air to move in both directions. This allows for higher torque and speed adjustment for valve automation.

Generally, pneumatic valves are best used for applications where valves are in a completely open or completely closed position. They do not work well for throttling. For throttling applications, other actuators may be more reliable.

In addition, it’s essential for easy access to compressed air to use pneumatic valve actuators in your facility. Some common facilities that use pneumatic valve actuators include:

- Chemical plants

- Refineries

- Compressor stations

- Power plants

- Water treatment facilities

- Mining operations

- Food and beverage production

Pneumatic Industrial Valve Actuator Repair

When you need pneumatic industrial valve actuator repair, our team is the ideal choice for your needs. We offer in-shop and field actuator repair to restore your valves to working order and minimize service interruptions.

There may be many different reasons why pneumatic actuators may fail. Our team can troubleshoot, repair, and test actuators before returning them to service.

Some common issues that may require pneumatic actuator repair include:

- Air leaks

- Plugged air ports

- Incorrect valve adjustment

- Damaged pistons

- Worn seals

- Damaged diaphragms

Our experts are here to identify and repair the root cause of failure for your industrial valve actuators. Our comprehensive severe service actuator repair technicians offer prompt response, quality repair, and quick turnaround for your repair needs.

Get in touch today to request actuator repair service.