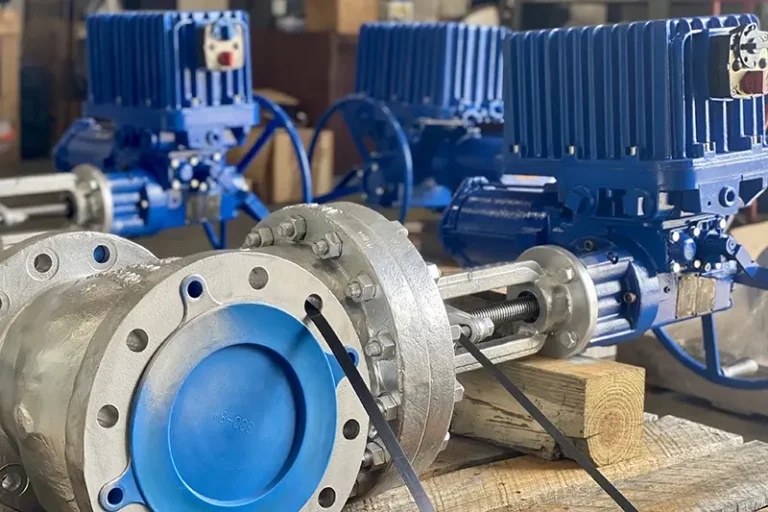

Industrial Valve Actuator Repair for Valve Stem Issues

Our seasoned actuator repair technicians are here to help diagnose and get to the root problem of actuated valve failure. One common cause of actuated valve failure is the valve stem. This is the part of the valve that moves the disk or ball to open and close the valve. Industrial valve actuators control process flow by acting upon the valve stem, whether through electric, pneumatic, or hydraulic power.

We provide unparalleled actuator repair services designed to extend actuator service life and reduce total costs of ownership for your facility.

Actuator Repair for Failed Stem Connector

One issue that may require industrial valve actuator repair is if the stem connector fails. The stem connector is the component of the actuator that connects the stem to the actuator’s center column drive. Depending on the type, the actuator then transfers energy from an electric motor, pneumatic pressure, or hydraulic pressure to move the valve stem.

With linear actuators, they move the valve stem in a linear direction. For rotary actuators, they twist the valve stem to control valve position.

However, if the stem connector fails, then you may lose actuation for your industrial process control valves. In cases like these, both the actuator and the valve may be functioning normally, but they are no longer attached to each other.

Our experts can help diagnose these issues and provide actuator repairs for stem connectors. If you have a failed stem connector, we likely need to replace the part. However, it’s also important to determine the root cause of failure. For instance, if the stem connector isn’t well suited to your application or to the valve and actuator types. Therefore, we may need to change the type of connection to provide quality actuator repair services that extend the life of the valve actuator.

Contact our actuator repair specialists today for troubleshooting, repair, and testing.

Repair for Worn Industrial Valve Stem

However, in some cases actuation failure may not be an issue with the actuator at all. Sometimes, it may be due to valve stem failure. In this case, actuator repair may not do any good. Fortunately, if our team finds that this is the issue, our teams at Southern Valve Service can provide the superior quality industrial valve repairs you need to restore functionality.

There may be many things that cause valve stem failure, with corrosion being one of the most common types of wear and tear. However, they may also fail due to damage from stress like over torquing.

Once again, it’s essential to understand the root cause of failure before providing repairs. For instance, it may be that the stem material may not be strong enough to withstand the forces from the actuator. In these instances, you may need actuator recalibration for lower torque, or you might need to replace the valve stem with stronger materials. Our teams can help get to the bottom of the issue and provide lasting repairs to reduce downtime and costs.

Get in touch now to request actuator repair services from our experienced professionals.